Are common ways of casting, casting difference is so big?

Release time:

2025-12-08

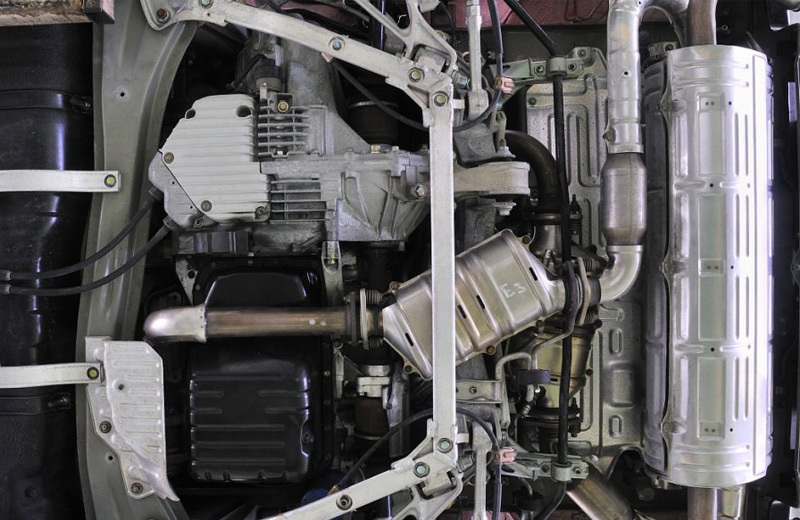

For the casting industry, gravity casting and foundry casting are among the more widely used casting methods, many industries will use these two casting methods when producing castings, often use these two ways to produce castings, do you know what is the difference between gravity casting and foundry casting production?

The castings produced by gravity casting machine have uniform wall thickness, high tissue density, smooth internal and external surfaces, consistent appearance size, and fast finishing speed. The casting produced by sand casting method is easy to include slag, sand hole, loose, rough internal and external surfaces, inconsistent shape size, slow finishing speed and inaccurate. In terms of yield, the product qualification rate of gravity casting machine is higher.

Gravity casting machine adopts gravity casting method, the casting temperature is low, the pollution is small, and the noise is small, but the coal furnace and oil furnace used in the production of castings by sand casting produce flue gas in the melting process, which is polluted and noisy. And the operation of gravity casting machine is simple, you can learn to operate, sand casting technology requires skilled operation, the cost is also the benefit of gravity casting to be high.

Latest News

Get a Free Consultancy

CONTACT US

Building B4, High-tech Industrial Park, 3177 Yuehe Road, Weifang Economic Development Zone, Shandong

Quick Navigation

Copyright©2024 Shandong Xiangying Tek Machinery Co., Ltd.